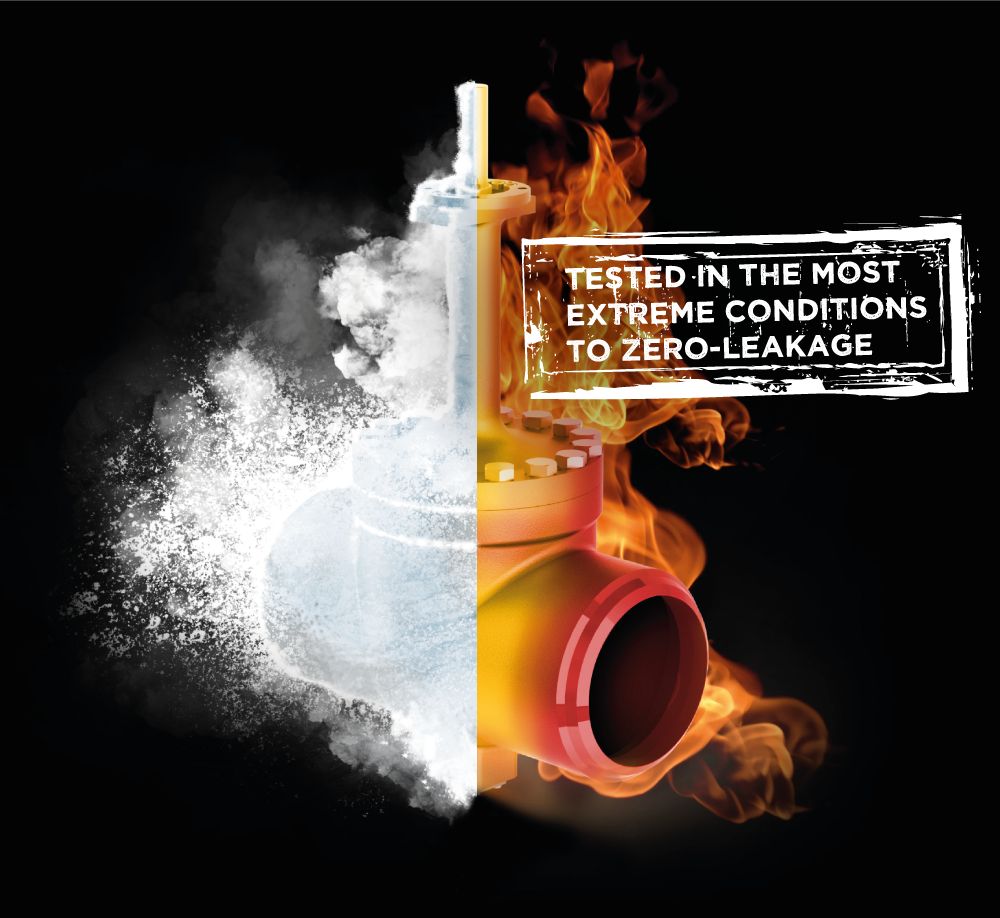

QUADAX® TOP ENTRY BUTTERFLY VALVE WITH ZERO LEAKAGE IN SEVERE THERMAL CYCLE AND ENDURANCE TESTS

QUADAX® Butterfly Valves outperform severe thermal cycle tests combined with an endurance test and has therefore been awarded in a large contract for replacement of Side Entry Valves in an existing LNG installation which will be extended by a new LNG terminal.

Natural gas is often described as the cleanest fossil fuel. It produces 25 – 30 % less carbon dioxide per joule delivered than oil and 40 – 45 % respectively than coal. Therefore the demand of LNG is steadily increasing and will become of high importance for many countries who want to add additional sources of supply.

On LNG terminals the imported liquid natural gas is unloaded from gas tankers at special berthing facilities and stored in large LNG storage tanks. In order to keep the gas liquified, the pipelines and the storage tanks withstand a temperature of -162 °C. Before delivering to the transmission network the liquified gas will then be smoothly warmed up and evaporated.

For these applications Top Entry Valves are preferred since the central top flange can be removed and all internal components can be easily extracted from the body. This is not the case for Side Entry Valves. Müller Quadax GmbH has been awarded for a large contract for Top Entry Butterfly Valves replacing Side Entry Valves in an existing LNG installation and for an extension with one new LNG terminal.

Located in Europe, this terminal enables access into the Northwest European gas market having an initial throughput capacity of 12 billion cubic meters per year (bcma), which in the future will be extended to 16 bcma. This terminal is also equipped with 3 loading bays for trucks and a dedicated jetty for smaller (bunker) vessels.

During storage and transportation natural gas could leak into the atmosphere particularly on critical components like measuring devices and process valves. Besides the negative environmental effect, these fugitive emissions could also have an impact on the security. The operating company of this LNG Terminal is therefore paying much attention to this fact and requested an individual performance test for the approval of cryogenic valves which shall be installed in their terminals and storage tanks. For this purpose the cryogenic test according to BS 6364 has been combined with an endurance test according to EN 12567. The Qadax® 4-offset butterfly valve DN 500mm, ANSI class 150 has been tested at the ITIS test laboratory in the Netherland specifiying 10 thermal cycles with a fugitive emission test at +20°C and at -196°C alternating. In addition the requirement called out an endurance test, with 500 mechanical movements at -196°C measuring the internal and external leakage after determined cycles. The benchmark in terms of the seat leakage was less than 3000ml/min for a valve of DN 500mm based on BS 6364 and a maximum allowable fugitive emission of ≤1.0·10-3 mbar∙l∙s-1 at any time of the cycles. The valve was tested with helium at 19 bar test pressure where as the seat leakage and fugitive emission was measured after 20/40/80/150/300 and 500 cycles.

1. LNG storage tank

2. High pressure pump

3. Open rack vaporiser

4. Sea water

5. Metering station

6. Send out toward gas network

7. Boil off gas compressor

8. Flare

9. Flare knought out (KO) drum

10. Boil off gas vapor return line

11. Unloading arm

12. LNG carrier

13. Unloading lines

14. Regasifier

15. Possibility to by pass

Thanks to the 4-offset design and a remarkable precision in manufacturing, the QUADAX® Butterfly Valves have provided once more the evidence of an outstanding performance, not only in high temperature but also in cryogenic applications.

The test institute ITIS BV certified that the seat leakage never exceeded a low value of 590 ml/minute and after 500 cycles zero leakage at all could be detected! Morover, the fugitive emission at the bonnet and trunnion gaskets of the Top Entry Valve never exceeded a value of ≤1.0•10-5 mbar∙l∙s-1. The round seat and sealing geometry of QUADAX® Butterfly Valves is a totally friction free metal to metal design. Thanks to this round geometry, after a couple of hundred cycles the seat and sealing ring is literally looped-in and provide highest tightness even if material is shrinking and expanding due to extreme temperature differences.

Conclusion

At the liquefication and storage process in LNG terminals the valves are critical components at each stage and its performance and reliability are crucial for environmental and safety reasons. The QUADAX® 4-offset Offset Butterfly Valve outperformed a severe thermal endurance test and provided evidence of its quality and reliability in LNG installations.

Additionally, QUADAX® Top Entry Butterfly Valves fully satisfy the requirements of the EN 1473-2016 specifications for valves and is specifically designed for LNG applications where control & maintenance work can be performed safe and easily in the installed position without further risks for the service personnel.