In thermal power plants, the combustion of fossil fuels or biomass water is converted into hot steam at up to 560°C.

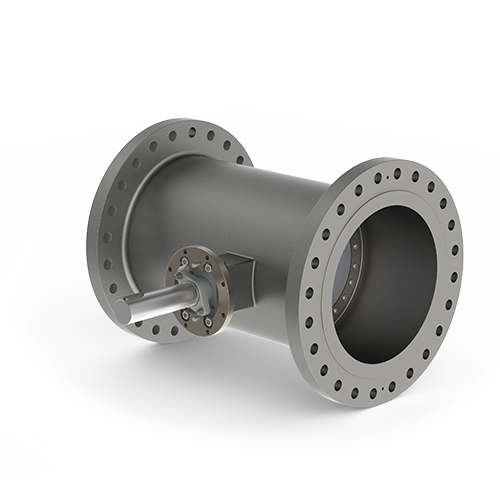

With this energy a steam turbine is driven which is coupled to a power generator. With the exhaust steam from the main turbine a so-called backpressure turbine is fed which is installed in a heat and power plant for district heating supply. Depending on the process, the temperature can still exceed +300° C with pressure ratios of up to 100 bar.

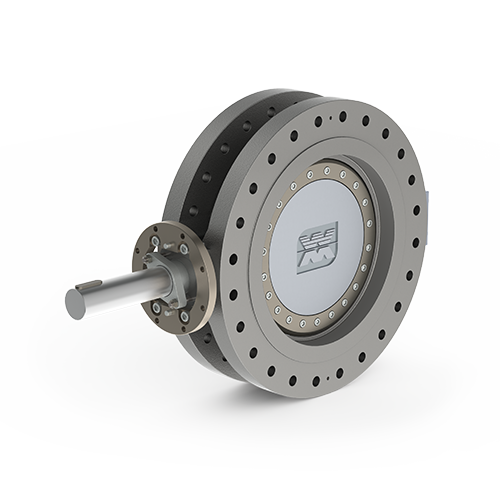

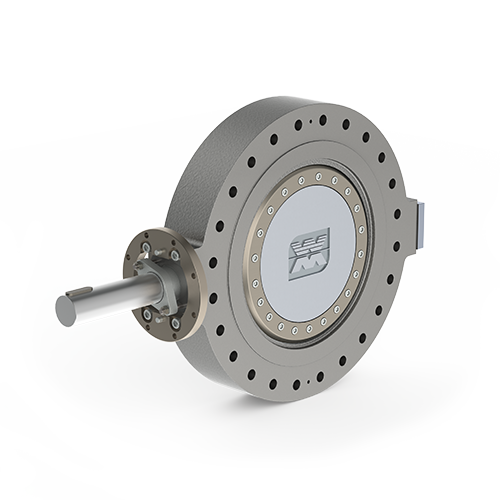

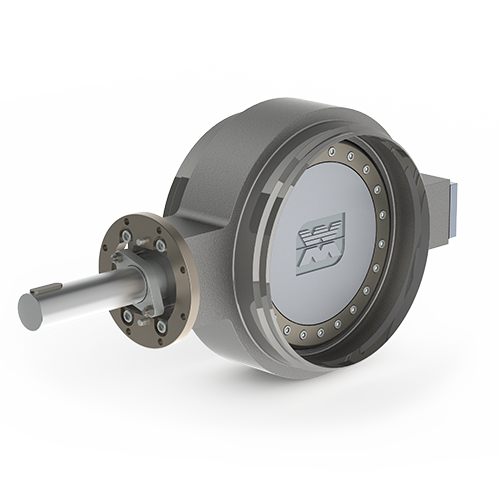

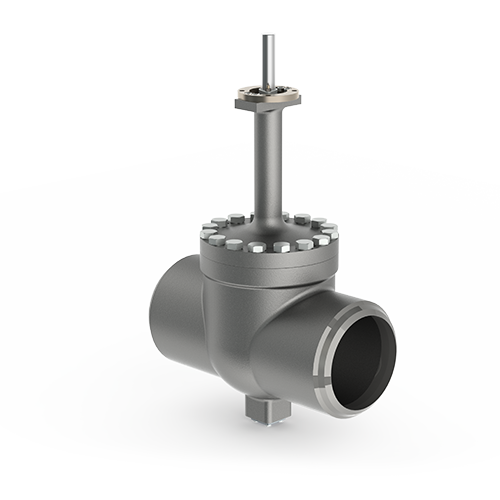

In a downstream condenser, the liquid decompressed steam is then cooled down to a range of approx. +70°C to +140°C depending on the heat demand before the warm water is delivered to industry or households via a district heating network. Quadax® valves guarantee the plant operators reliability, efficiency and longevity at full capacity and bubble tightness.

With this energy a steam turbine is driven which is coupled to a power generator. With the exhaust steam from the main turbine a so-called backpressure turbine is fed which is installed in a heat and power plant for district heating supply. Depending on the process, the temperature can still exceed +300° C with pressure ratios of up to 100 bar.

In a downstream condenser, the liquid decompressed steam is then cooled down to a range of approx. +70°C to +140°C depending on the heat demand before the warm water is delivered to industry or households via a district heating network. Quadax® valves guarantee the plant operators reliability, efficiency and longevity at full capacity and bubble tightness.

OTHER APPLICATIONS

THAT MIGHT INTEREST YOU